Manufacturing

ENVIRONMENTAL CONTROL

ASSEMBLY LINES

PLASTIC MOULDING

BASE COATING PLANT

SMT LINE (SURFACE MOUNT TECHNOLOGY)

INTEGRATED HARD COATING

LEARNING CENTRE

TOOL ROOM

administration

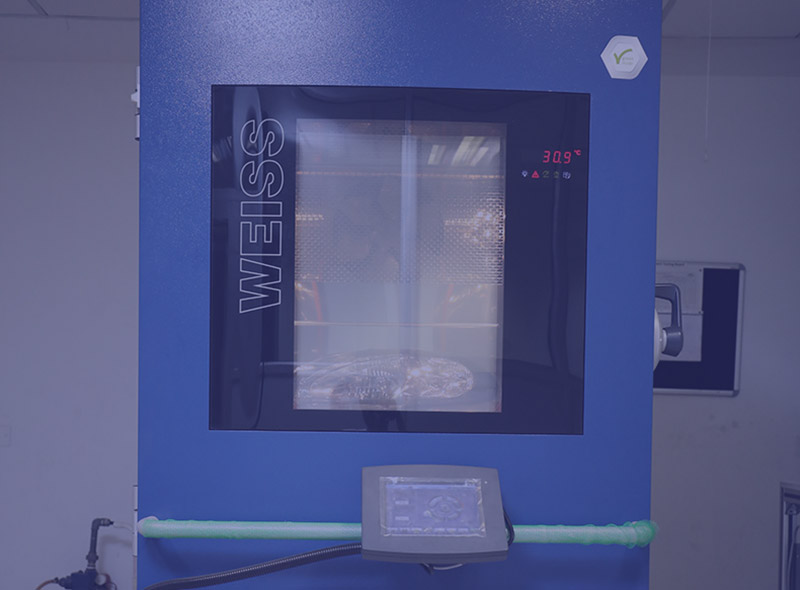

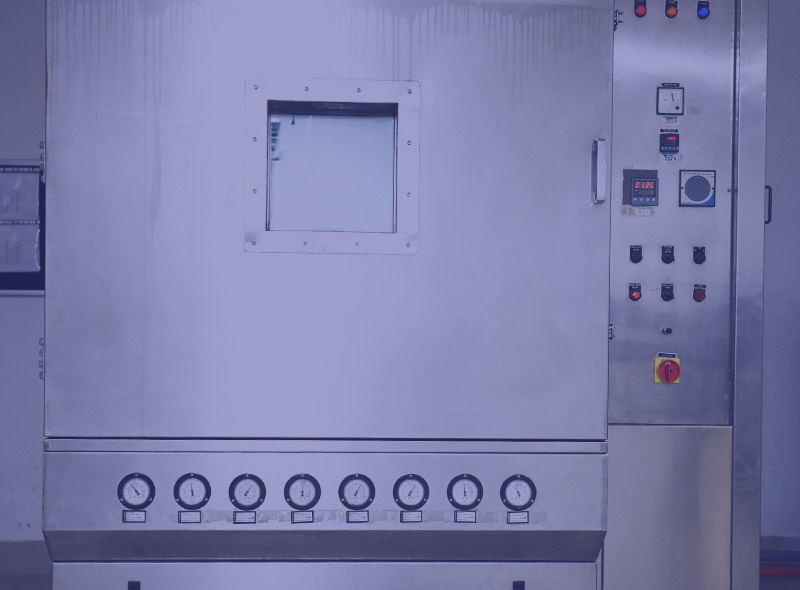

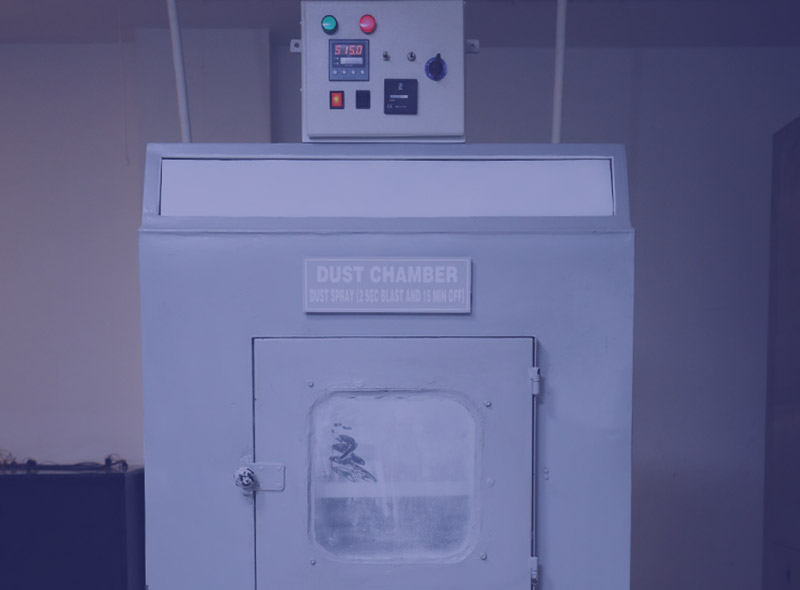

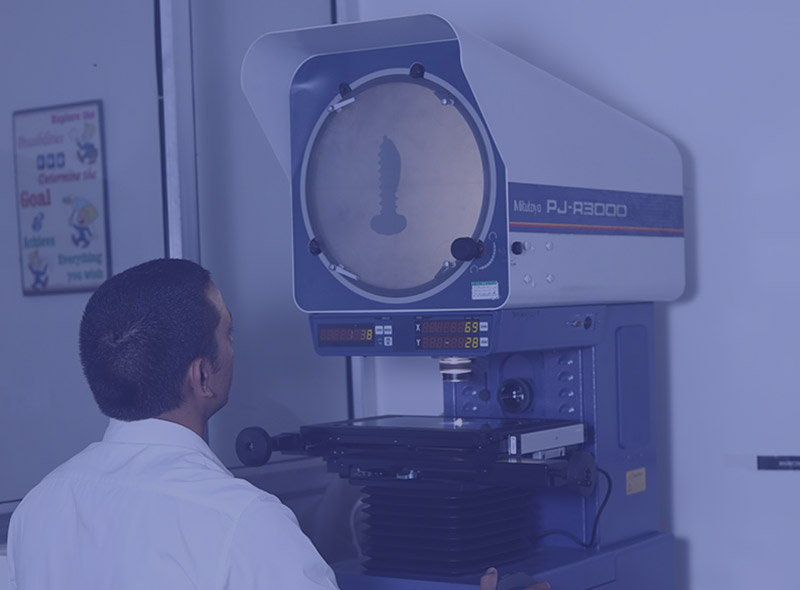

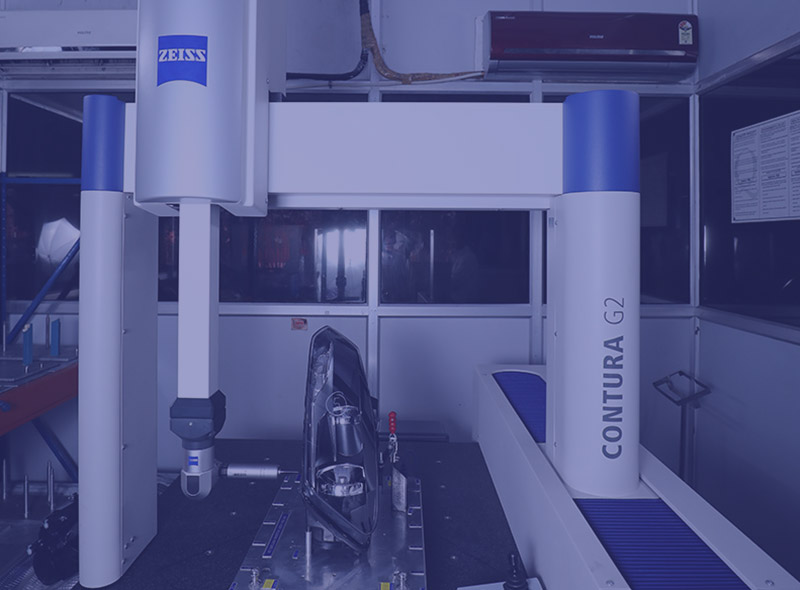

Testing

Fully equipped Testing Laboratory to meet test standards, such as:

- AIS Regulations i.e. AIS-012, 010 & 062.

- ECE Regulations i.e. ECE- 6, 7, 8, 19, 20, 23, 50, 57, 112 and 113

- SAE-DOT / FMVSS 571:108

- JIS D-5500