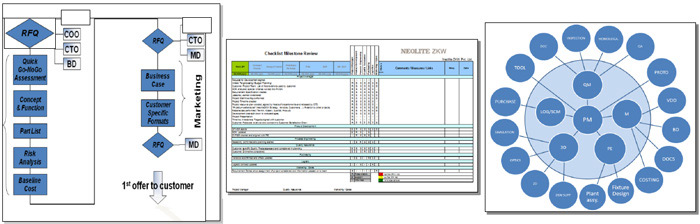

PROJECT MANAGEMENT

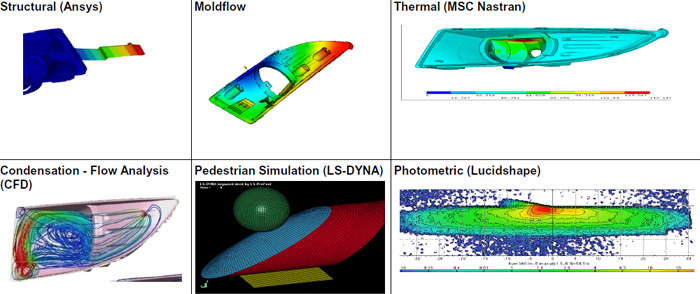

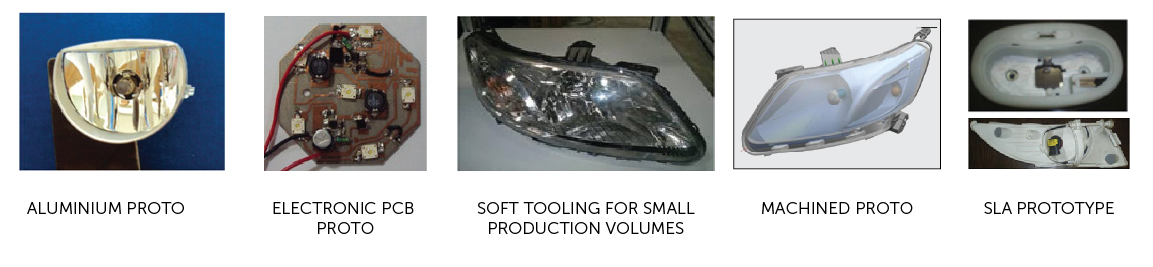

Sophisticated CAD/CAM systems allow rapid three dimensional modeling and design. State-of-the-art software allow, finite element analysis that ensures accurate detailed design techniques. With the development of a New Product Introduction Process Guide, cost effective product designs are assured for every level of production. The result is a highly reliable design consistent with the manufacturing processes to be used.

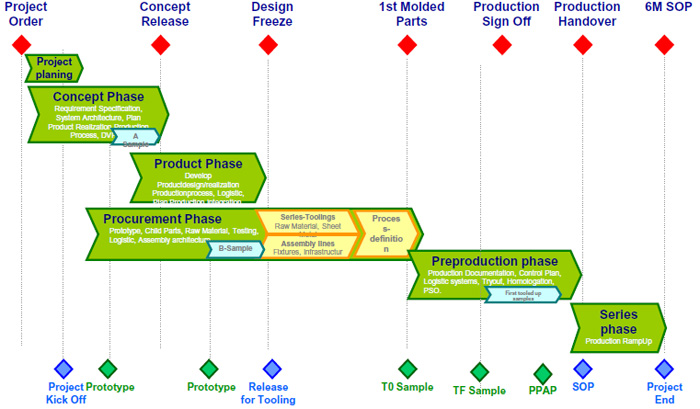

We support a comprehensive state of the art Project Management System that engages Cross Functional Teams who work based on Role Descriptions, Check sheets and Process Flow Charts to successfully bring the product from Feasibility to Start of Production ensuring Product-Quality, -Cost and -Time. Re-use, Lessons Learned and Best Practices are applied to overall improve product design and product ppm-rates. The Project Manager is the direct interface to the customer Project Team.